A snare drum built for Purpose.

Every snare drum starts with wood, a nice piece of wood. Choosing the right piece for the size of the snare and with the correct thickness to reduce waste.

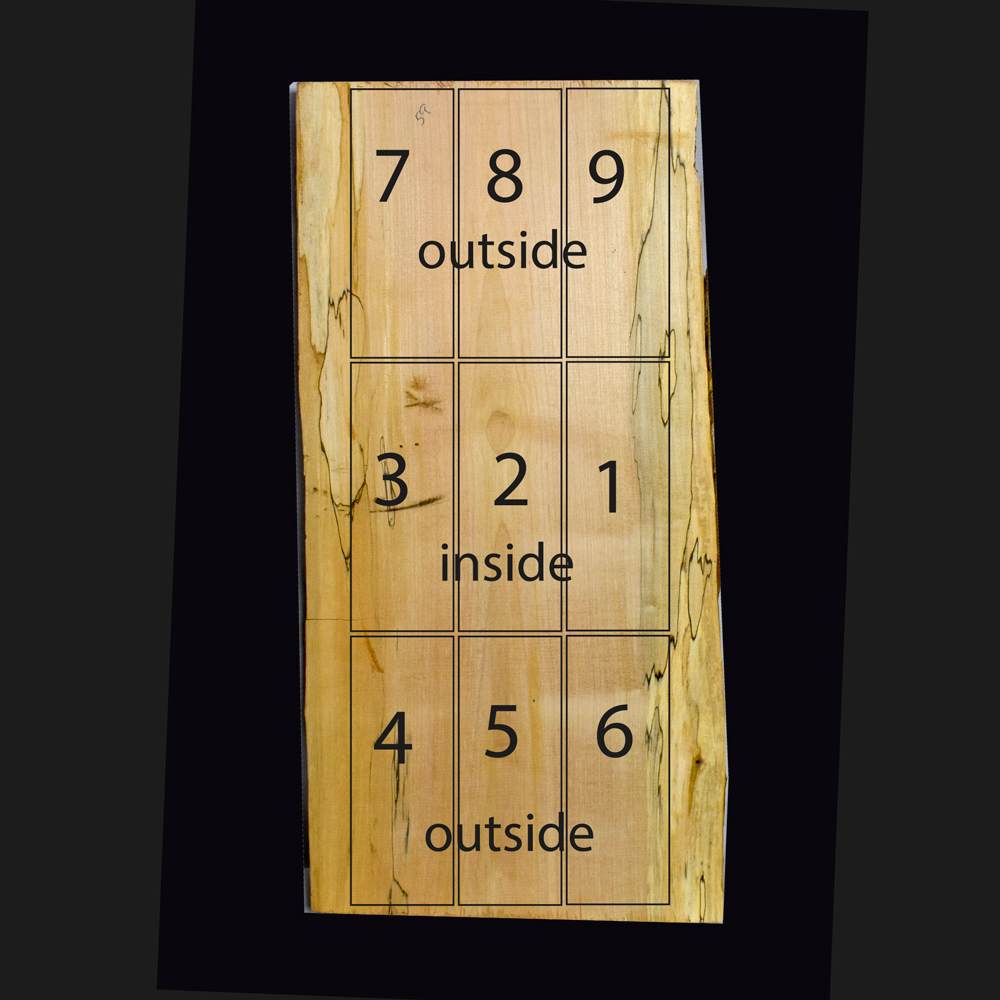

I work with sustainably sourced, local wood, and I don’t just grab the first board that looks good. Each piece is measured and planned for maximum use and minimal waste. After collecting the wood, I make a picture of it and work out the best cutting schematic, and even figure out the best layout to get a head start.

Making the Shell.

The staves are initially cut slightly wider than they need to be. Then I dry fit the staves to check if the bevel cut is accurate. If not, I can adjust the angle and work my way to the correct diameter of the 14-inch shell.

Before glueing, I sand the bevel cuts in order to get the best contact between staves and often get invisible seams.

Shaping the snare drum shell.

I have made a special jig for shaping the shell quicker and more efficiently than what you see from the competitors. This approach lowers the cost of making a stave snare drum, which in turn makes the consumer price also lower. You, too, can now own a handmade custom snare drum that has unmatched sound qualities.

Finishing the Wood.

When the drum shell has its final shape, the bearing edges are done.

Only then do I level the shell, and after levelling, I recut the bearing edges using the last setting of the router. This again reduces effort and time to make the snare drum shell perfect, without you having to raid your bank account to own one of these.

After the first sanding is done, I check the shell for any defects, especially at the bearing edges. Wood has natural imperfections that are not beneficial for the sound of the snare. When needed, I fill the imperfections with wood filler. The woodfiller is not to hide any imperfections; it is to end up with a perfect surface.

Hardware, Made to Fit.

The tube lugs are made in-house to reduce the cost of buying them in and then converting them. Because the tube lugs and strainer are bolted on the outer ring chassis, the snare can easily be tuned without the need for any special tools. The hardware ring can also be used with your own snare drum shell or any other 14-inch shell that you bought elsewhere.

Unlike other floating systems, this system is fully free-floating, only uses simple and conventional parts, and can be used universally. (minimum shell depth: 5.5 inches, maximum shell depth: 7.5 inches)

More Than a Drum.

I can not be clearer about this: this snare is built for the best possible sound, not for special looks. A stave, or segment shell that has wood inlays or intricate patterns, will not make the snare sound better or even differently. This fully free-floating snare designreferences back to the original snare from centuries ago, when the snare started as a free-floating snare with rope attached to the top and bottom hoops.